What’s More Important - Suit Fabric or Suit Fit?

Suits have been around for a while. The OG suit, the original, sartorial standard of dress, can be traced back to the 17th century when King Charles II decreed a dress code for men of the English Court. Two hundred years later, in the late 19th century, Englishmen Beau Brummell said “f off” to frock coats and powdered wigs (phew) and brought to market the first version of the modern suit we all know and love today.

So what’s changed since then? A lot. But the age-old question remains - what’s most important in a suit… fabric or fit? What’s also interesting is that this answer itself has changed over time, so we’ll talk about where it’s been and where it’s going. But first, let’s put down some baselines on each to contextualize this debate. For both fabric and fit, we’re going to assume a base level of quality. Obviously, if you’re 5’10 and the suit was made for someone 6’4” - not going to work. If the fabric is full of low quality synthetics and is poorly made, it’s not going to look great no matter how well it fits.

In this post we’ll focus on the battle that suit brands are waging against each other, off-the-rack vs. made-to-measure and Italian milled luxury fabrics vs. generic quality fabrics. What’s the short answer? Well, it’s complicated. But don’t worry - this isn’t one of those posts that ramble on just to get to an “it depends” answer. Let’s look at the facts.

1. FABRIC - Varying Qualities & Synthetic Materials Used In Suiting Fabrics

Synthetics Are Much Higher Quality Than Years Past

Historically, synthetic fabrics were a big no-no in the suiting world. The polyester suits of the 90s were stiff, hot and just looked… bad. These poor fabrics are easy to weed out and you can usually tell just by looking at it. Generally speaking, avoid suit fabrics that are primarily polyester content.

However, synthetics fabrics and blends have made huge strides in the the past 5-10 years. Take a look at your athletic wear or a dry fit golf shirt - changes are it's 100% polyester. It's soft, stretchy, breathable, comfortable. That was unheard of not all that long ago.

This isn't to say that suits made out of all or primarily synthetics is a good thing - most people can certainly tell the difference between a premium wool suit and a fully synthetic “8-way stretch” suit. The wool looks a heck of a lot better. So for suiting, we still recommended sticking to mostly natural fabrics - wool, silk, cashmere, cotton, linen.

Natural / Synthetic Blend Fabrics Have Advantages

While the suit purists will strongly advocate against any synthetics in suiting fabrics, we believe this is an outdated stance that while valid in years past, no longer holds water. There are a number of advantages that a bit of synthetic material offers, including:

Durability: Synthetic fibers like polyester and nylon are known for their strength and resilience. When blended with natural fibers, they enhance the fabric's overall durability, reducing the risk of tears and wear, especially in high-stress areas like elbows and knees.

Wrinkle Resistance: Synthetic fibers tend to be less prone to wrinkling than natural fibers like wool or cotton. This means your suit will maintain a more polished appearance throughout the day, even if you're on the move.

Affordability: Suits with a blend of synthetic fibers are lower cost than those made entirely from premium natural materials. This makes them a cost-effective option for individuals seeking quality suiting that doesn't break the bank.

Stretch and Comfort: Blending in a small amount of elastane or spandex can add stretch and flexibility to the fabric, making the suit more comfortable to wear, especially when you're on the go.

The right blend depends on what properties you’re looking for and what weather conditions the suit is best for. A bit of polyester doesn’t hurt - 99% of people won’t be able to tell the difference, including the person wearing it - but stay away from polyester content higher than 30%. Is 100% wool better than 90% wool 10% polyester? Technically, yes. But can anyone tell the difference? No, except for your wallet. Merino wool might be a tad softer, but if it’s double the price, is that worth it? For some people yes, but for the bulk of the market it’s a status symbol more than it is a measurable difference in perceivable quality.

Fabric Production Is Largely Commoditized

In recent years, fabric making, like many products over time, has become highly commoditized. Think about this logically -- the process is largely done by machines, and the steps aren't that complex. If you have the right machines, you can make high quality fabrics. Is that 150-year old italian mill actually any better than a vietnamese one using the same machines, materials and processes? Other than the name recognition, no, it’s not.

So while many brands are hawking their fabrics that are “italian-milled” at the “highest quality” production facilities in the world, what they’re really saying – to be blunt – is that you’re overpaying for a fabric tag that few people but you will ever know about. At this point, the name of the mill a fabric is produced is more of a marketing gimmick than something of tangible value. Many countries around the world are now producing high quality fabrics. The difference is simple, they don’t have the name brand association, and they don’t come with an overinflated price.

To put this simply - once you reach a baseline of quality, where the fabric is produced doesn't make much of a difference. Yes merino wool might breathe a bit better, but most people won’t be able to tell. Yes the fabric produced from an esteemed 150-year old italian mill is likely “better”, but by how much? Is it worth paying 200%-400% more for fabric that's maybe 20% better?

The Verdict... blends are fine and great fabrics aren't only made in Italy.

Don't shy away from suiting options just because they have a bit of synthetic in them. From a value standpoint, a 90/10 or 80/20 blend could look just as nice as 100% merino wool and cost a fraction of the price. We're all about great value at Sartoro, and that's why our fabric collection is hand selected to provide the best balance of quality and price.

2. THE SUIT FIT -- Off-The-Rack vs. Made-to-Measure vs. Bespoke

On the other side of the debate is the suit fit. Similarly to the fabric choice, fit also matters, but it's not black and white either. Styles have changed dramatically from decade to decade, and fashion culture has made some---interesting---decisions in the past. If you’ve watched The Last Dance, you’ll see what I mean with the suits NBA players were wearing back in the 90s. In the new 20’s, it’s all about fitting your body.

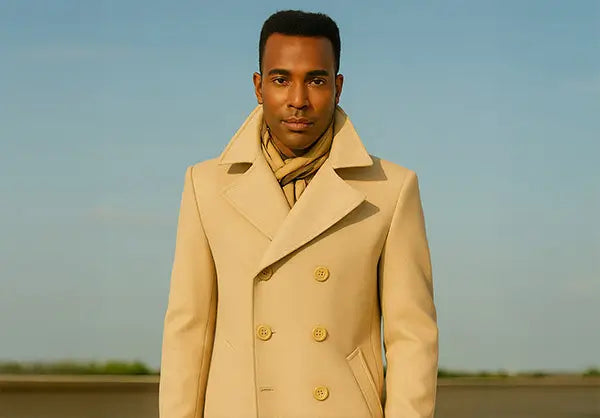

Out are the days of oversized shoulder pads, pleated pants and box-shaped jackets of the Michael Jordan era. In is the slim, trim look of a suit that conforms to the wearer’s unique body type, accentuating their best features and presenting a more polished appearance.

Today’s market offers three primary ways to buy a suit, with three different levels of suit fit: off-the-rack, made-to-measure (custom), and bespoke. We’ve summarized the difference below - for more details, see our post that compares them more in depth.

Off-The-Rack: Wallet Friendly, Works For Some

Off-The-Rack (OTR) suits are mass produced based on set sizes (38S, 42R, 46L, etc). The sizes are akin to an expanded version of small, medium and large that t-shirts come in. While the expansion of sizing options helps get a “closer” fit to an individual's specific body size, it’s not hard to tell when a suit fit is OTR. Whether it’s the shoulder width or sleeve length, something will be off. Minor corrections can be made, but this is limited. These mass produced suits also produce the most waste and contribute to the clothing industry being among the most harmful for the environment.

Made-To-Measure: A Hybrid Model for an Enhanced Fit

Made-To-Measure (MTM) suits are a hybrid model that uses pre-set patterns (OTR sizes) that are adjusted based on the customer’s measurements. This results in a better initial suit fit that, like an OTR suit, can be altered slightly later to further improve the fit. MTM is a large step above OTR, and factories have been optimized to produce these at scale.

Most online “custom” suit brands offer made-to-measure, even if they are labeled as custom, which is a bit different than what the term traditionally meant. Customers with unique body shapes may still struggle to get a great fit, even with the advantages offered by this manufacturing method.

Bespoke (Custom): The Highest Level of Suitmaking Precision

Bespoke suits are the creme de la creme of suit making. Rather than adjusting a pre-cut pattern, bespoke suits use the individual's measurements to create the pattern used for the garments that is unique to that one individual customer. You’ll always get the best suit fit from bespoke as the garment is made for one person… you. As you might expect, this is the most expensive and time consuming manufacturing method as mass production isn’t possible.

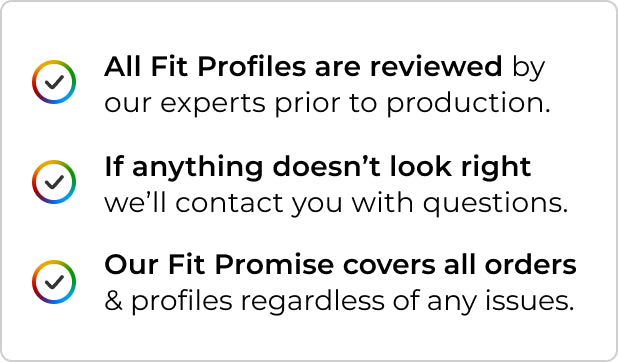

Traditionally, bespoke suit making requires many visits to the tailor for fittings and adjustments, sometimes 5 or more. Sartoro has turned this model on it's head, delivering bespoke made garments from an all-online store, without the need for in-person fittings. While any online only custom suit brand will never be able to produce as perfect of a fit as a true bespoke experience, we're able to deliver an incredible suit fit for 4-5x less than the average cost of a classic hand-made bespoke suit.

The Verdict... Fit Matters... a lot.

The way a suit fits is the first thing anyone (you included) will notice when you’re wearing the suit. A great fitting suit doesn’t just look great, it feels great. The subtle differences are tough to pick out one by one, but collectively across the entire suit make a world of difference.

And the winner is... Suit Fit. By a Landslide.

Simply put, the best fabric in the world on a OTR suit will never look as nice as a decent fabric on a MTM or bespoke suit. So you can go pay $2000 for an off-the-rack Gucci suit, and it might look “cool”, but it's not going to fit or look as polished as a suit custom made for you.

As mentioned, fabric production is now largely commoditized - you don’t need the fabric to come from an italian mill for it to be of high quality. The suit fit, on the other hand, is far more differentiable. Construction methods, consistency and quality are very important.

While bespoke offers the best fit, these suits are often (but not always) significantly more expensive, and the added cost for most consumers isn’t worth the noticeable but small improvement over MTM.

However, companies like Sartoro are making high quality bespoke suits affordable for all. How? Two ways.

1. By eliminating expensive storefronts and moving the entire process online. Without any physical stores, costs are lower and less markup is required. When you walk into a high end suit store in NYC, you better believe a big portion of the cost you’re paying is for the exorbitant rent, the plush leather couches, the single malt scotch you’re served during fittings and the cost of the staff. Do you really want to pay for all that? We didn’t.

2. By leveraging expert international tailors for their world class talent and affordable labor costs. Hoi An, Vietnam is well known as the garment capital of southeast Asia. Tailors are exceptionally talented and fair wages are far lower than in the west. The same level of quality in the US costs 4-5x more.

But how are accurate measurements taken if everything is online? Easy - Sartoro's Digital Tailor can predict body measurements to within 3%, all with just a few basic inputs, no measurements required. And just in case something isn’t perfect, an alteration credit is included with every Sartoro suit - and first orders can be returned if you don't love it.

Every suit brand offers different options and different suit fits. Deciding which elements matter most to you is a personal choice. Well-known brands have been able to charge exorbitant prices for OTR suits, and for some consumers, the brand tag is most important. But for the savvy suit buyer, a focus on fit will almost always result in a better garment, and in some cases, a lighter impact on the wallet, too.