STEP OUT IN CONFIDENCE, ARRIVE IN STYLE

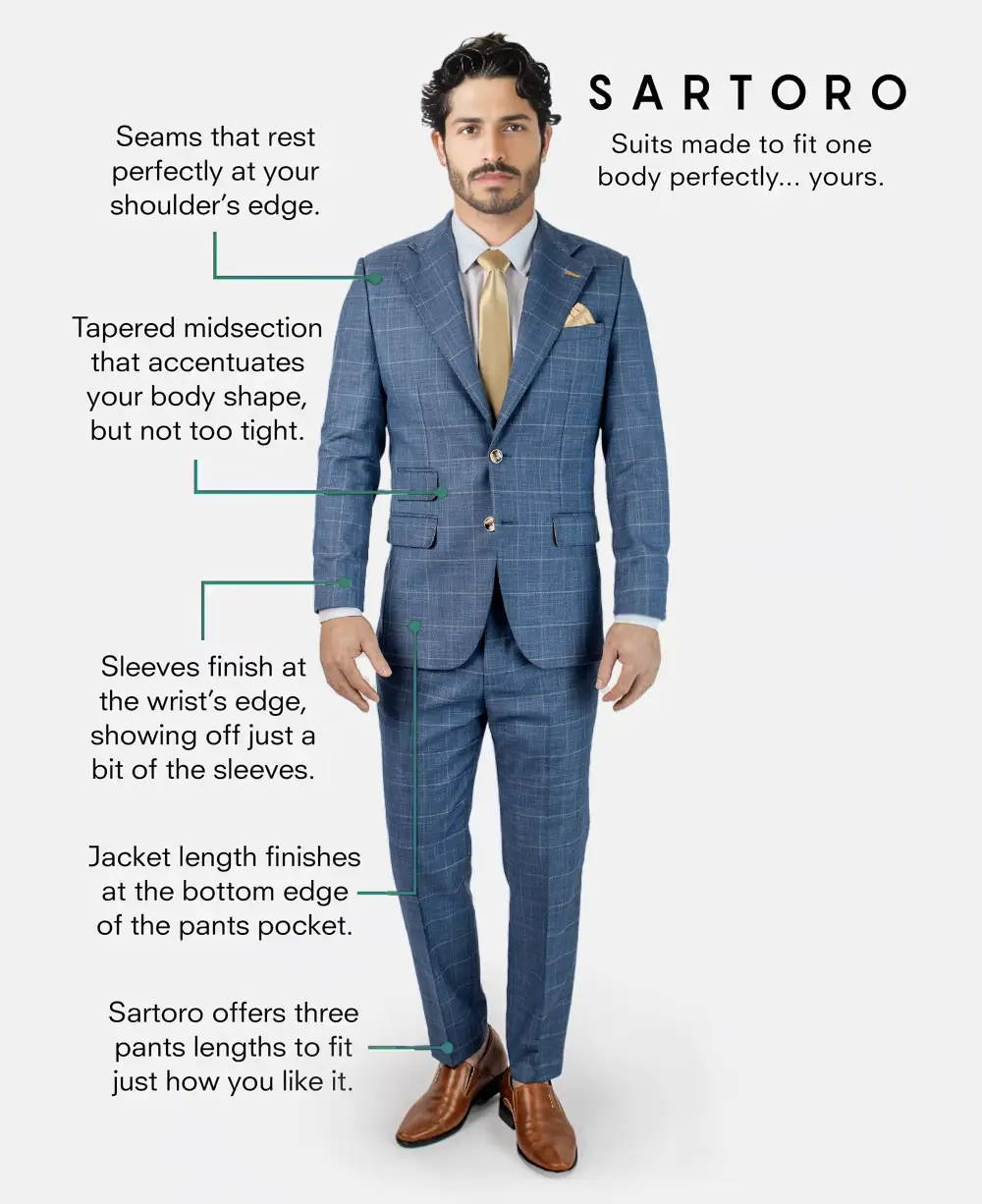

Experience the feeling of a suit made to fit

one person... you.

Get a free $99 Shirt with any suit purchase.

Add both to your cart & use code: FREESHIRT

100% fit guarantee & free first order returns.

Free 1st Order Returns If You Don't Love It

300+ Five Star Reviews

Our customers tell the story. Over 170 reviews on-site, 100+ on TrustPilot (4.8/5.0 Score), 50+ across other sites. <1% return rate.

FREE First Order Returns

First Order Returns

Returns on custom made clothing? You bet. If you're not happy with your first Sartoro purchase, send it back for a full refund.

free Alterations & Remakes

Alterations & Remakes

Worried it won't fit? If you have any issues, we cover alterations and if necessary will remake the garments quickly. Learn more.

"Your New Favorite Suit - A fusion of New York

design & comprehensive personalization"

"Streamlined & sophisticated... the easiest

way to get a great custom fit online"

300+ Five Star Reviews

Our customers tell the story. Over 170 reviews on-site, 100+ on TrustPilot (4.8/5.0 Score), 50+ across other sites. <1% return rate.

FREE First Order Returns

First Order Returns

Returns on custom made clothing? You bet. If you're not happy with your first Sartoro purchase, send it back for a full refund.

free Alterations & Remakes

Alterations & Remakes

Worried it won't fit? If you have any issues, we cover alterations and if necessary will remake the garments quickly. Learn more.

STAY WARM IN CUSTOM MADE STYLE

Buy A Coat

Get A Shirt

Yep, coats too! Use code: FREESHIRT

9 Colors. Choose your style, length & weight.

100% fit guarantee & free first order returns.

Custom clothing that’s easy to order, affordable & great value

Your New Favorite Suit - A fusion of New York design & comprehensive personalization in a seamless experience

"Your New Favorite Suit - A fusion of New York

design & comprehensive personalization"

Custom clothing that’s easy to order, affordable & great value

"Streamlined & sophisticated... the easiest

way to get a great custom fit online"

Your New Favorite Suit - A fusion of New York design & comprehensive personalization in a seamless experience

UPGRADE ANY LOOK WITH A CUSTOM FIT

UPGRADE ANY LOOK

Jackets & Blazers

Jackets

& Blazers

Bold styles and classic threads. Design yours.

100% fit guarantee & free first order returns.

Premium craftsmanship.

Custom experience.

We didn't reinvent the tailoring wheel... we just made it better. Modern technologies woven into a better online experience drive efficiencies that raise quality and reduce your cost.

Custom made by in-house world class tailors

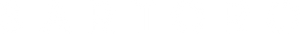

One minute measurements, with a fit guarantee

Industry leading delivery in as little as two weeks

Premium craftsmanship.

Trusted by over 3000.

We didn't reinvent the tailoring wheel... we just made it better. Modern technologies woven into a better online experience raise quality while reducing your cost. Over 3000 customers have made the Sartoro switch.

Custom made by world class tailors

Industry leading 2-3 week delivery

One minute measurements,

backed by our Fit Promise

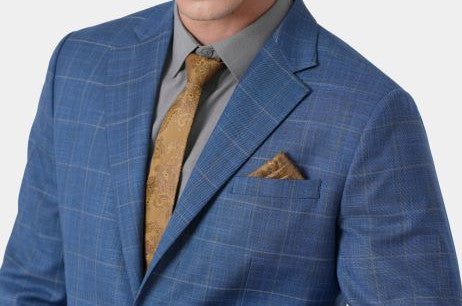

Top Selling Suits

All Sartoro suits are crafted by our team of expert tailors with decades of collective experience.

Whether you're purchasing for work, leisure, or for your wedding - you're receiving a garment made exclusively for you.

Top Selling Suits

All Sartoro suits are crafted by our team of expert tailors with decades of collective experience.

Whether you're purchasing for work, leisure, or for your wedding - you're receiving a garment made exclusively for you.

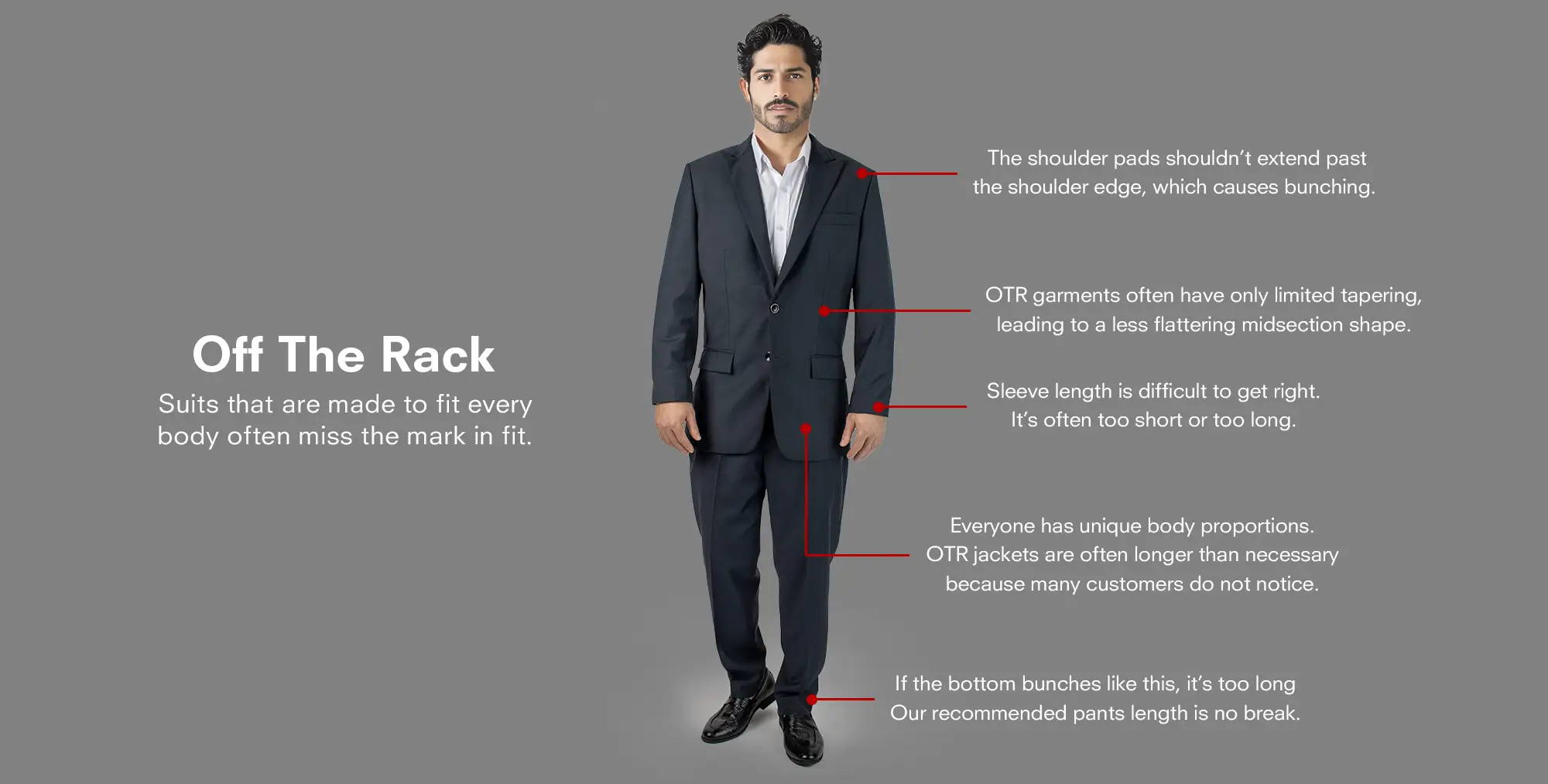

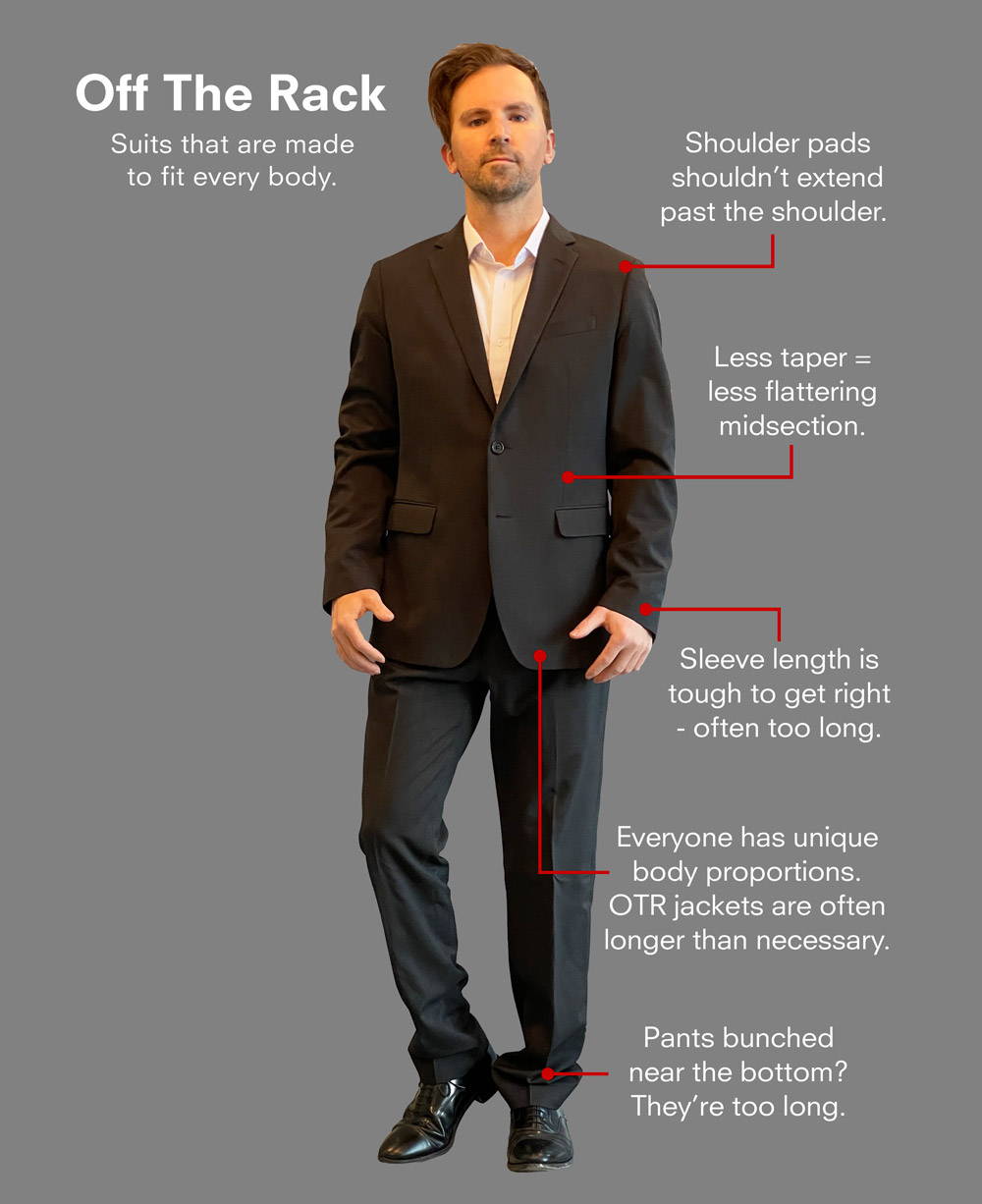

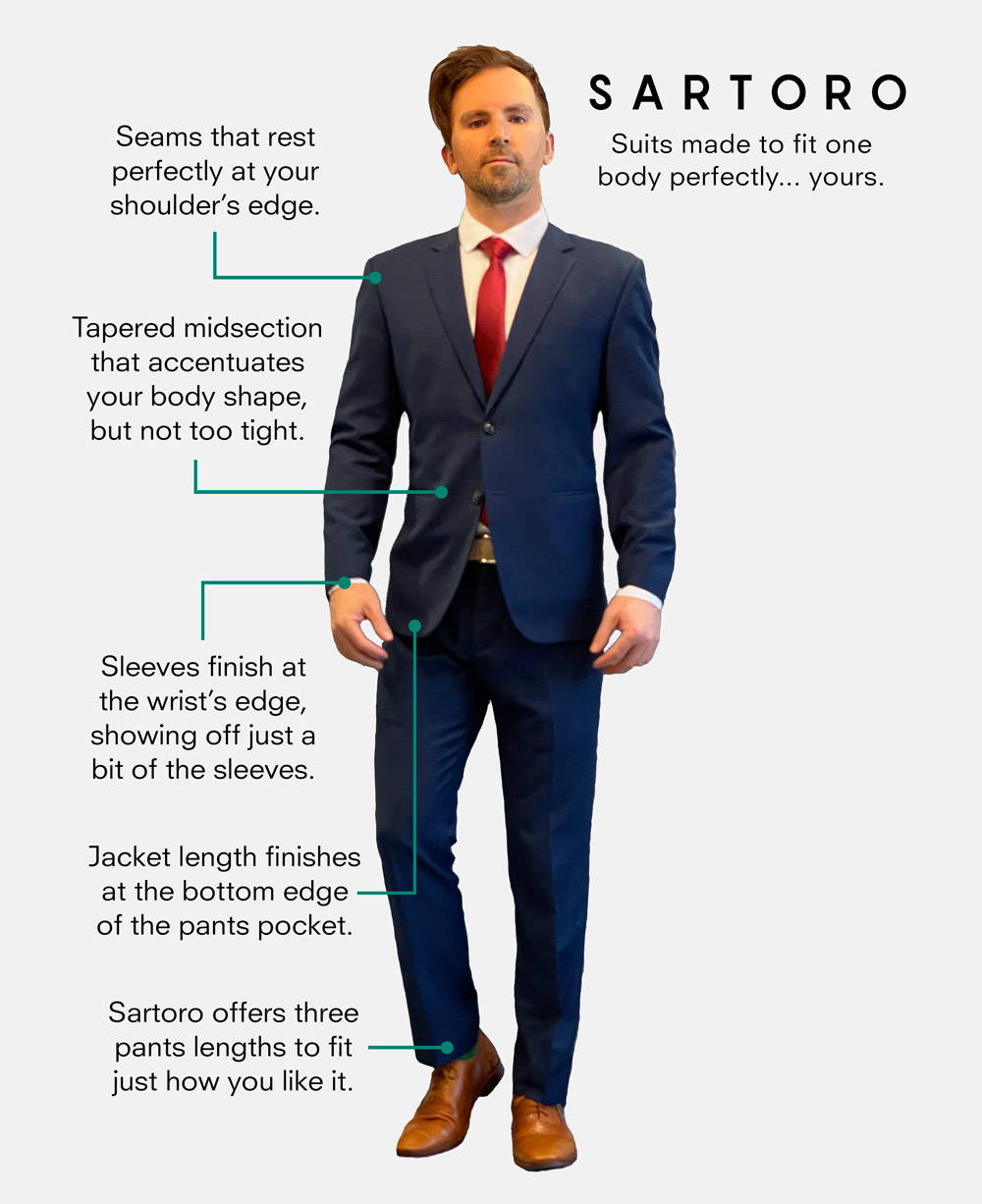

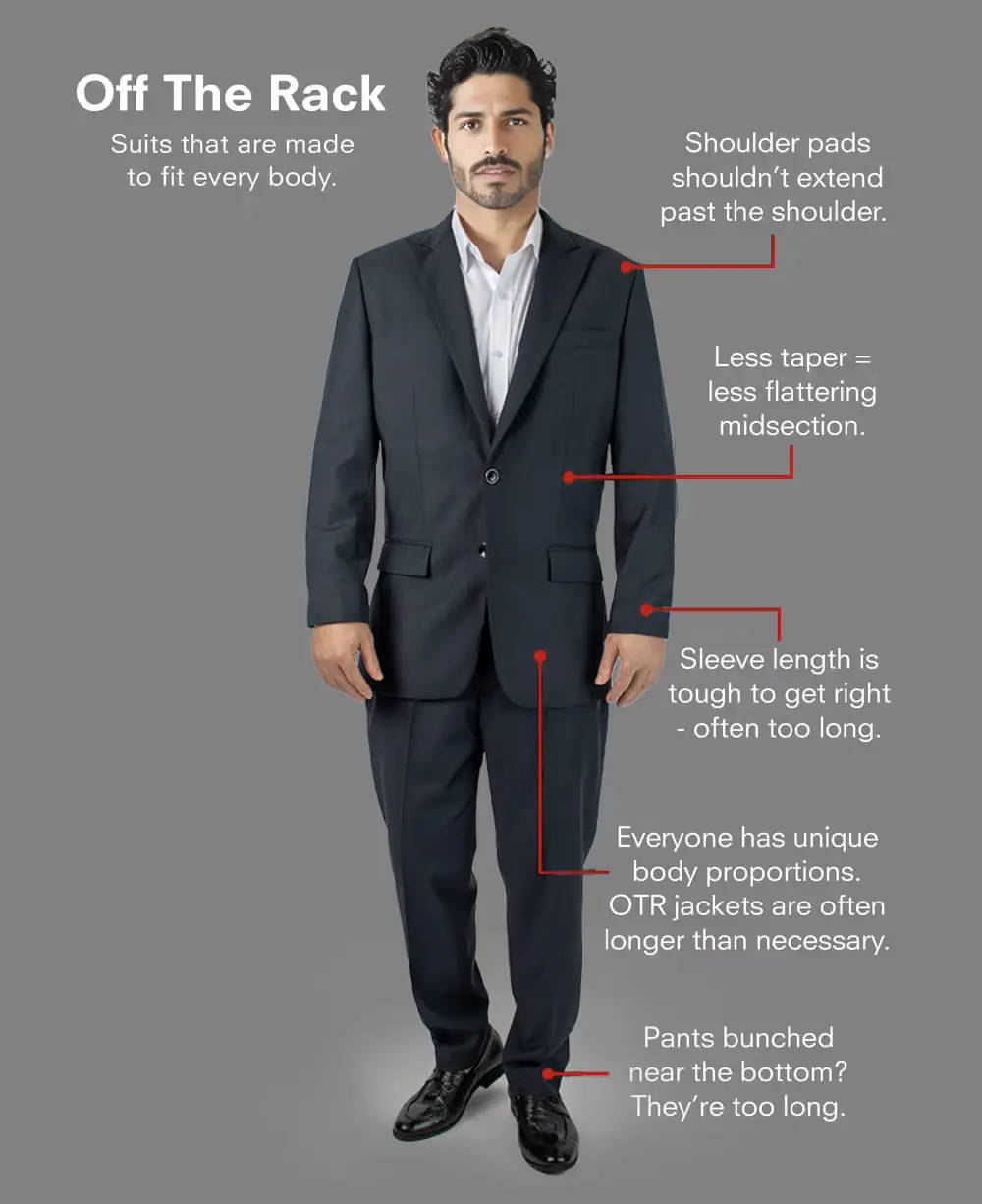

Tired of off-the-rack clothing that just doesn't look quite as good as it should?

We were too. So we set out to make premium custom clothing easy, approachable & affordable.

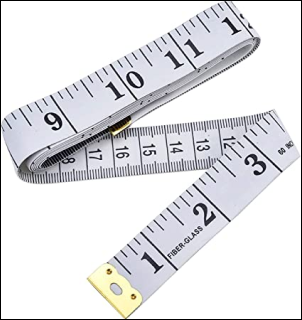

Getting the perfectblazer| is as easy as...

Choose your fabric

With over 120 fabrics to choose from, we have something for every occasion. Want to see the fabric first? Order samples. Just remember - these deals will be gone soon. With free first order returns, shop risk free.

Choose

your fabric

With over 120 fabrics to choose from, we have something for every occasion. Want to see the fabric first? Order samples. Just remember - these deals will be gone soon. With free first order returns, shop risk free.

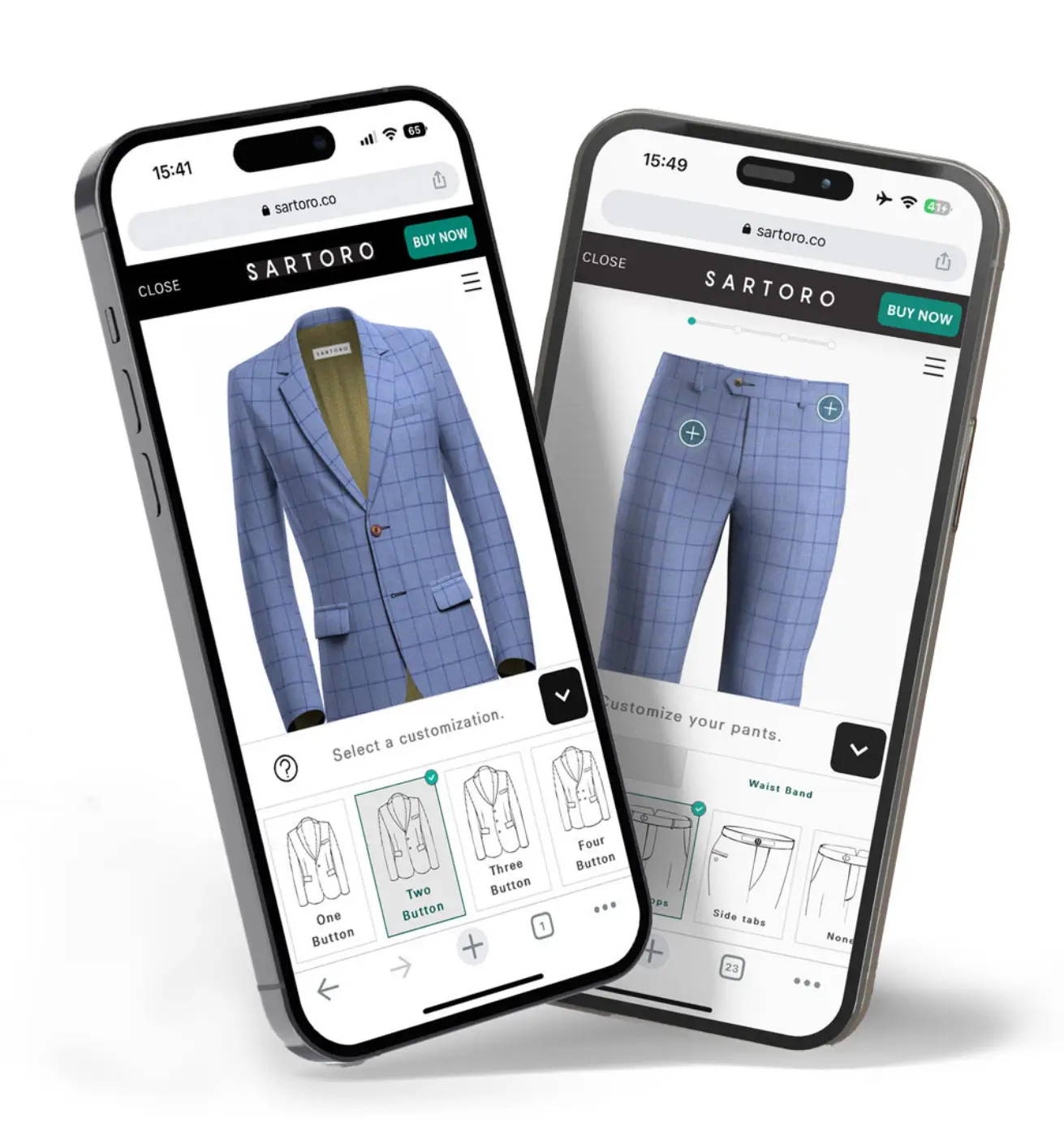

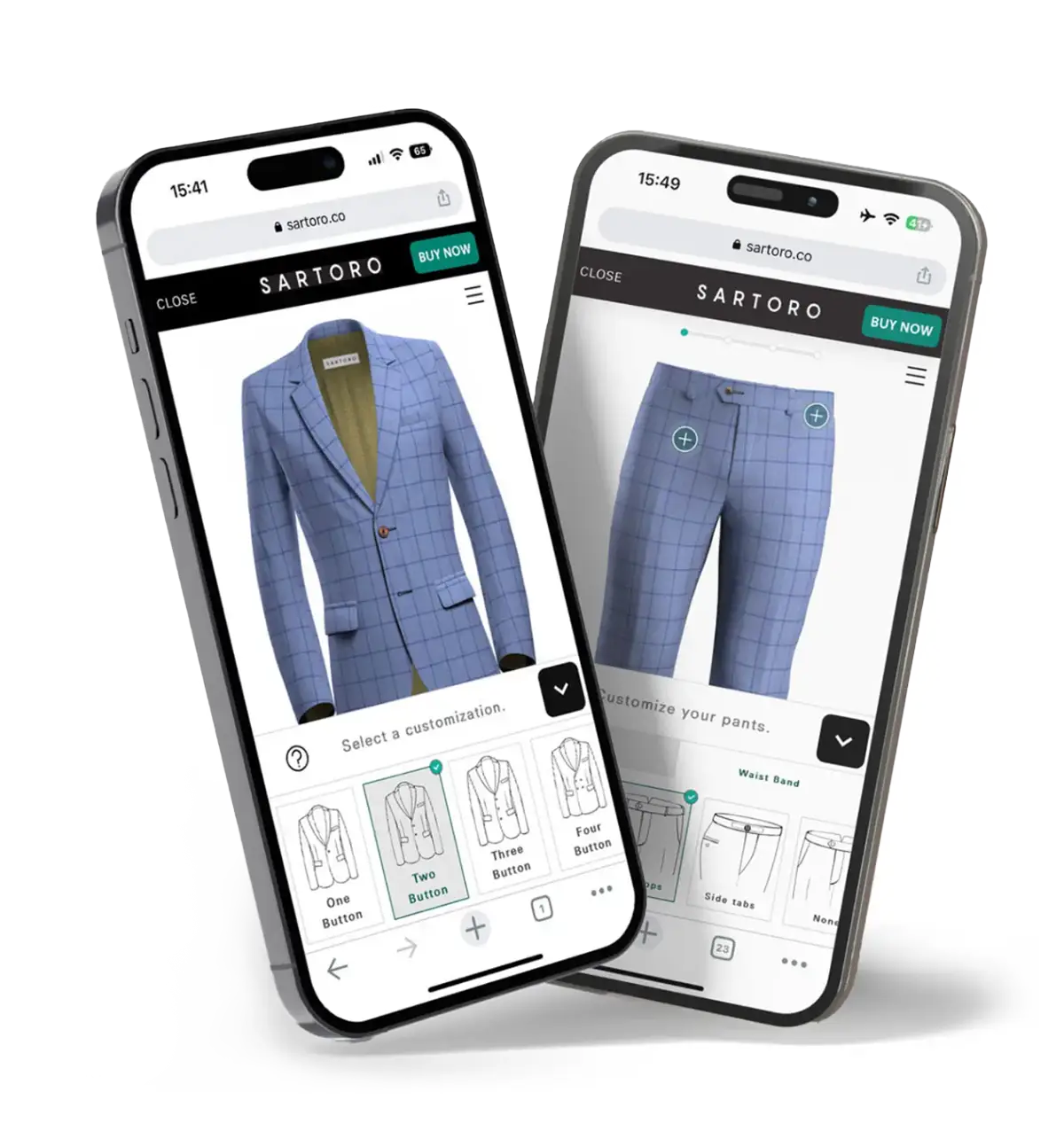

Customize your style

Our state-of-the-art suit designer allows you to visually design your garments in real time. Choose everything, from the jacket type to the buttons, pockets, lining and more.

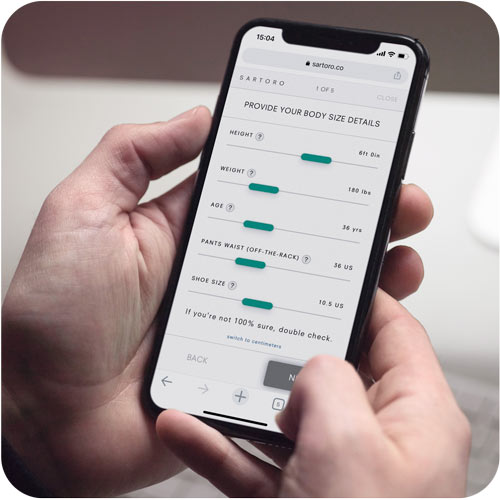

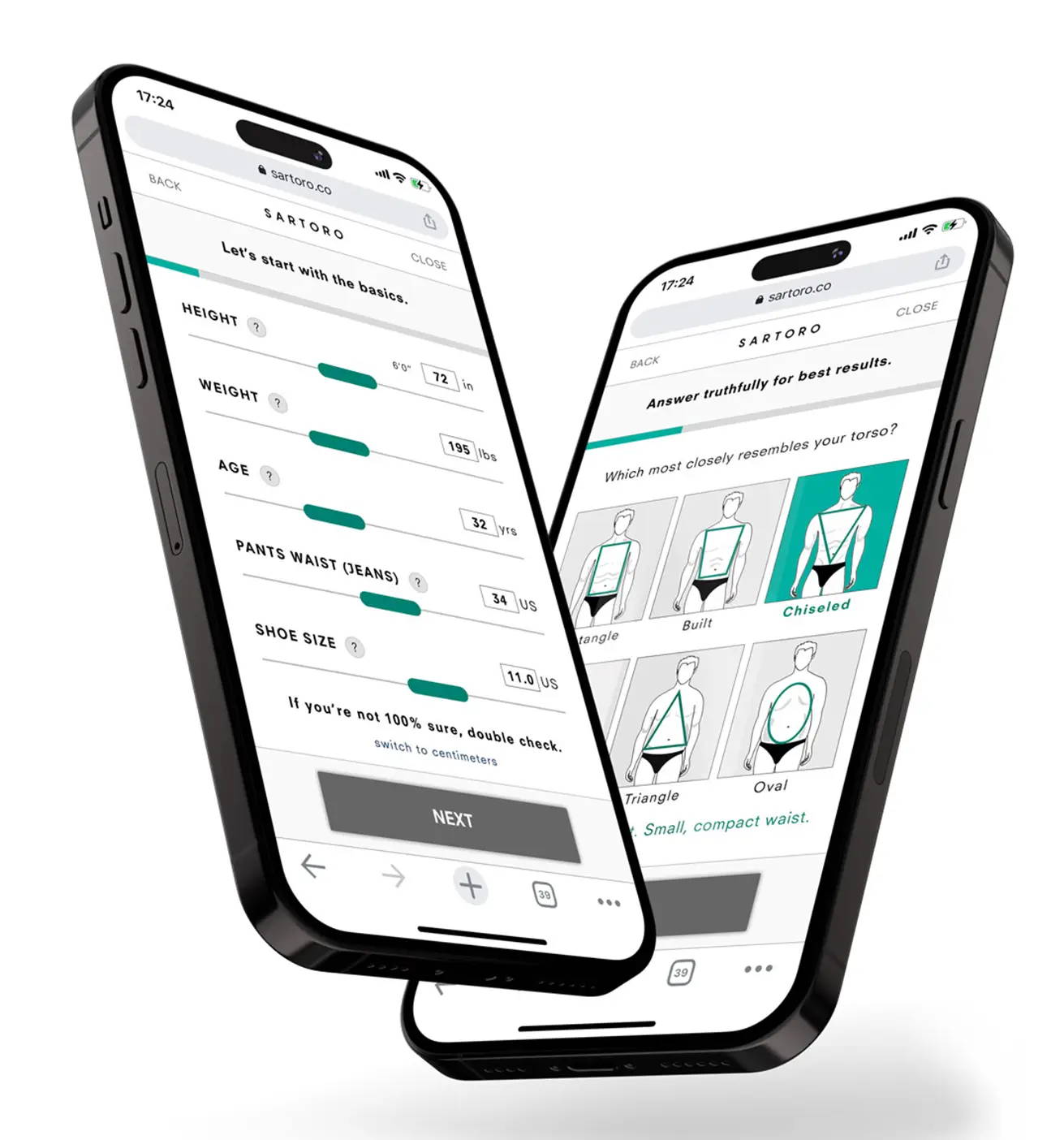

Get fitted in a minute

Our AI-powered Digital Tailor will get you measured for custom garments fast - without you having to pick up a tape measure. Industry-leading tech, backed by our Fit Promise.

Upgrade to Custom. See the Difference.

Customize

your style

Our state-of-the-art suit designer allows you to visually design your garments in real time. Choose everything, from the jacket type to the buttons, pockets, lining and more.

Get fitted

in a minute

Our AI-powered Digital Tailor will get you measured fast - without you having to pick up a tape measure. Industry leading tech, backed by our Fit Promise.

Upgrade to Custom. See the Difference.

What if it doesn't fit?

Only a small percentage of first orders require adjustments, and we offer the following options:

free Alterations

Have the garments adjusted locally. We'll reimburse

you up to the covered limits. More Info

free REMAKES

Way off the mark or alterations will be too expensive?

We'll remake the garment(s), for free. More Info

Covered Alterations

Have the garments adjusted locally. We'll reimburse you. More Info

Free Remakes

Way off the mark? We'll remake the garment(s), for free. More Info

See how our suits are made

Half Canvas

An inner layer of horsehair + cotton canvas gives the jacket structure & form. This slightly more casual drape is the preferred modern style, and reduces the unnecessary price of full canvas construction.

Half Canvas Standard

An inner layer of horsehair + cotton canvas gives the jacket structure & form. The slightly less rigid drape of a half canvas is the preferred modern style, and has the added benefit for you of reduced cost over full canvas.

See how our suits are made

Your Personal At Home Tailor

Your Personal

At Home Tailor

We make the process of going custom simple, fast and effective. Our garments are made with care by our small team of dedicated craftsmen. We pride ourselves on providing a level of service that matches the premium quality of our custom clothing.

Custom Suits

From $469

Custom Coats

From $449

Custom Jackets

From $349

Custom Vests

From $119

Custom Pants

From $129

Custom Shirts

From $99